Brinell Hardness Number Test Calculator

Material Science Testing Equations Formulas

Problem:

Solve for Brinell Hardness Number.

Enter Calculator Inputs:

Can you share this page? Because, it could help others.

Solution:

Solution In Other Units:

Input Unit Conversions:

Change Equation or Formulas:

Tap or click to solve for a different unknown or equation

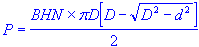

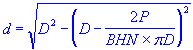

| Brinell Hardness Number |

| load |

| depression diameter |

References - Books:

Lindeburg, Michael R. 1992. Engineer In Training Reference Manual. Professional Publication, Inc. 8th Edition.

Background

The Brinell Hardness Test, developed in the early 1900s by Swedish engineer Johan August Brinell, is a method for determining material hardness. The test measures the material's resistance to deformation, specifically from a hard spherical indenter. This method has been broadly adopted for its simplicity and ability to test materials with a coarse or uneven grain structure.

Optimizing testing methods like the Brinell Hardness Test is crucial in many industries to ensure material durability and appropriateness for specific uses. The Brinell Hardness Number measures how hard a material is. This number helps in choosing the right materials and ensuring quality. As industries change, this testing method stays important for both production and research. It helps guarantee safety, efficiency, and innovation in product development.

Equation

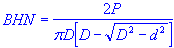

The Brinell Hardness Number (BHN) is calculated using the formula:

Where:

- P = applied load in kilograms-force,

- D = diameter of the indenter in millimeters,

- d = diameter of the impression left by the indenter in millimeters.

How to Solve

Selecting the Indenter and Load: Choose a suitable indenter diameter and load for the tested material.

Applying the Load: The load slowly to the material until it reaches the chosen force.

Measuring the Impression: Once the load is removed, measure the diameter of the impression left by the indenter.

Calculating BHN: Use the impression diameter, the applied load, and the indenter diameter in the BHN formula to calculate the Brinell Hardness Number.

Example

Suppose a test is performed with a 10mm steel ball as an indenter with a force of 3000kg applied, leaving an impression diameter of 5mm on the material. The BHN can be calculated as:

Thus, the Brinell Hardness Number of the material is 187.96.

Common Material Brinell Hardness Number

These values serve as a general guide. For precise measurements and applications, refer to material specifications or perform direct hardness testing under standardized conditions.

- Lead: Around 5 BHN

- Tin: Approximately 7 BHN

- Zinc: Roughly 40 BHN

- Aluminum: Varies widely, but pure aluminum is about 15 BHN, while some aluminum alloys can range up to 150 BHN

- Copper: Pure copper is around 35 BHN, but bronze and brass (copper alloys) can range from 60 to over 150 BHN

- Mild Steel: Typically ranges from 120 to 180 BHN

- Tool Steel: Depending on the specific alloy and heat treatment, can range from 200 to over 600 BHN

- Cast Iron: Varies from about 120 to over 250 BHN depending on type (gray, ductile, etc.)

- Stainless Steel: Ranges widely based on grade, from about 150 BHN for austenitic grades to over 600 BHN for precipitation-hardened grades

- Titanium: Commercially pure (Grade 1) titanium is around 70 BHN, while some titanium alloys can exceed 350 BHN

Fields/Degrees It is Used In

- Metallurgy: For assessing the quality and grading of steel and other metals.

- Engineering: To determine the suitability of a material for a specific application.

- Manufacturing: For quality control of materials used in machinery and automotive industries.

- Aerospace: In testing components that require particular hardness levels for safety and performance.

- Research & Development: Helps develop new materials and improve existing ones.

Real-life Applications

- Automotive Industry: In testing gears, shafts, and axles for hardness.

- Construction Equipment: Ensuring the durability of metal frames and hydraulic components.

- Jewelry Making: In determining the hardness of precious metals like gold and platinum.

- Machining Tools: In testing the hardness of cutters and blades to ensure longevity and efficiency.

- Pipe Manufacturing: Testing the hardness of metal pipes used in high-pressure environments.

Common Mistakes

- Incorrect Indenter Load: Using a load that is too light or heavy can result in inaccurate measurements.

- Improper Measurement: Not accurately measuring the diameter of the impression can lead to incorrect BHN.

- Inadequate Surface Preparation: Testing on a dirty or rough surface can alter the impression diameter.

- Using a Damaged Indenter: A worn-out indenter can distort the results.

- Ignoring Material Thickness: Failing to ensure the material is thick enough to avoid indentation errors.

Frequently Asked Questions

- What is the difference between BHN and Rockwell hardness?

BHN measures the indentation hardness of materials through the scale of penetration of an indenter, while Rockwell hardness measures the penetration depth. Both serve similar purposes but use different scales and methods. - Can BHN be converted to other hardness scales?

Yes, conversion tables and calculators are available to approximate the equivalent hardness values on different scales. However, due to the nature of other tests, direct conversions may only sometimes be accurate. - What materials can be tested using the Brinell method?

Most metals, especially those with coarse or uneven grain structures, can be tested. It is not suitable for very hard or very soft materials. - Is the Brinell test destructive?

Yes, it leaves a permanent indentation on the tested material, which might not be desirable for finished products. - How do I choose the correct indenter and load?

The choice depends on the material being tested and the standard being followed. Generally, softer materials require a larger indenter and lighter load, whereas harder materials need a smaller indenter and heavier load.

Online Web Apps, Rich Internet Application, Technical Tools, Specifications, How to Guides, Training, Applications, Examples, Tutorials, Reviews, Answers, Test Review Resources, Analysis, Homework Solutions, Worksheets, Help, Data and Information for Engineers, Technicians, Teachers, Tutors, Researchers, K-12 Education, College and High School Students, Science Fair Projects and Scientists

By Jimmy Raymond

![]()

Contact: aj@ajdesigner.com

Privacy Policy, Disclaimer and Terms

Copyright 2002-2015