Subwoofer Box Comparison Calculator:

JavaScript version of all three calculators (Bandpass, Sealed and Vented)

JavaScript version of all three calculators (Bandpass, Sealed and Vented)

Sealed Subwoofer Example

This is an example on how to use AJ Sealed Designer to build a sealed/closed enclosure. The following will be discussed:

- Speaker/Driver Specifications

- Speaker/Driver Selection

- Input Parameters

- Box Results

- Box Designer

- Box Construction

Speaker or Driver Specifications:

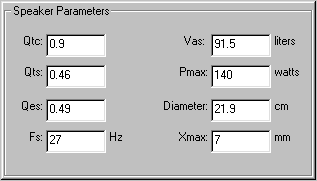

The following speaker parameters were provided with the data sheet that came with a 10 inch speaker.

- Qts = 0.46

- Qes = 0.49

- Fs = 27 Hz

- Vas = 3.23 ft^3

- Vas = 91.5 liters (performed a conversion to get Vas in liters)

- Pmax = 140 watts

- Diameter = 9 inches

- Diameter = 21.9 cm

- Xmax = 4.0 mm

Note, the input for diameter is 9 inches not 10 inches. The diameter is the measured diameter of the actual speaker cone. Do not include the speaker frame diameter for this value.

Speaker parameters should have come in the packaging/literature with speaker. If they are not available contact the manufacture to obtain any missing speaker parameters. Also, most manufactures have their current driver data on their web sites

Speaker or Driver Selection:

Sometimes, a speaker is designed or engineered for a specific enclosure. On the other hand, a majority of woofers can be used in various enclosure types.

As a rule of thumb, use the following equation to determine the suitability of your speaker.

Suitability factor = fs / Qes

Factor less than 50 the driver is best suited for a sealed enclosure

Factor between 50 and 100 the driver can be used for both sealed and vented enclosures

Factor above 100 the driver is best suited for a vented enclosure.

Use these factors as an estimation. For example if you want to build a sealed enclosure and the factor of the speaker is 55, the speaker should do fine in a sealed enclosure. The speaker suitability value is in the vicinity of the sealed factor.

The speaker being used has a Suitability factor of 55 which meets the criteria for a sealed enclosure.

This was determined by the following calculation:

Suitability factory = fs/Qes = 27/0.49 = 55

As a rule of thumb, use the following equation to determine the suitability of your speaker.

Suitability factor = fs / Qes

Factor less than 50 the driver is best suited for a sealed enclosure

Factor between 50 and 100 the driver can be used for both sealed and vented enclosures

Factor above 100 the driver is best suited for a vented enclosure.

Use these factors as an estimation. For example if you want to build a sealed enclosure and the factor of the speaker is 55, the speaker should do fine in a sealed enclosure. The speaker suitability value is in the vicinity of the sealed factor.

The speaker being used has a Suitability factor of 55 which meets the criteria for a sealed enclosure.

This was determined by the following calculation:

Suitability factory = fs/Qes = 27/0.49 = 55

Input Parameters:

The speaker parameters are entered into Sealed Box Designer Speaker Parameters group box:

Qtc is a user defined parameter. Qtc is related to the amount of dampening the enclosure will provide the back surface of the speaker cone. As the box size increases, dampening decreases, because there is more air space. Higher Qtc values increase the dampening effect and decrease volume. There is no "perfect" value for Qtc. Values between 0.4 and 1.2 should give good results. A value of 0.7 will give a flat response.

Note how the volume of the box (Vas) increases or decrease as the value of Qtc is varied.

A Qtc of 0.9 was chosen, because the enclosure is going into the trunk of a car and space is an issue. A higher Qtc results in a smaller box.

Note how the volume of the box (Vas) increases or decrease as the value of Qtc is varied.

A Qtc of 0.9 was chosen, because the enclosure is going into the trunk of a car and space is an issue. A higher Qtc results in a smaller box.

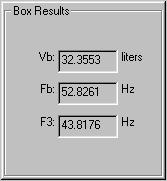

Box Results:

The following parameters were calculated after pressing the Calculate button.

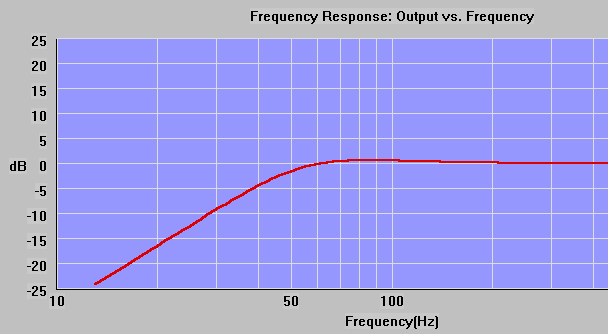

A Vb of 32.35 liters results in a relatively small box with a F3 of 42.8 Hz. The F3 value will provide good bass extension, because a sealed enclosure has a -12 dB/octave roll-off. A vented enclosure have a -24 dB/octave roll-off. The Frequency Response vs. Frequency plot is as follows:

Note how a hump or dip develops and how the F3 value changes as you increase or decrease Qtc

Box Designer:

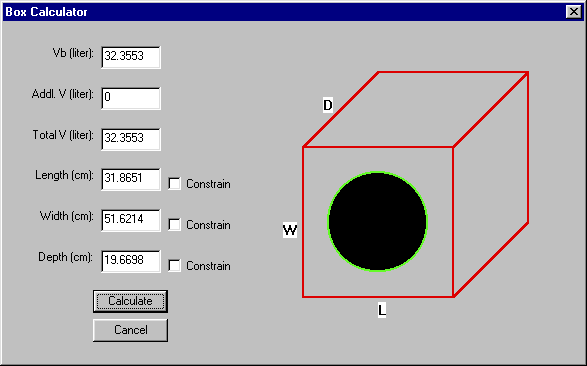

Next, the Box Designer function is used to calculate the internal dimensions of the box.

The box dimensions using the Golden Rule calculations are as follows:

The box dimensions using the Golden Rule calculations are as follows:

Doing some conversions, the dimensions of the box are determined in English units:

Remember, Box Designer determines the internal dimensions of an enclosure. Building material thickness will have to take into account when building the enclosure.

1 inch high density particle board was used for the enclosure material. The boards dimensions used for construction are as follows:

For more information on Sealed Box Calculator, click here.

- Length (L) = 31.9 cm = 12.6 inches (approximately 12 1/2 inches)

- Width (W) = 51.5 cm = 20.3 inches (approximately 20 1/4 inches)

- Depth (D) = 19.7 cm = 7.76 inches (approximately 7 3/4 inches)

Remember, Box Designer determines the internal dimensions of an enclosure. Building material thickness will have to take into account when building the enclosure.

1 inch high density particle board was used for the enclosure material. The boards dimensions used for construction are as follows:

- 2 boards 22 1/4 inches by 14 1/2 inches

- 2 boards 20 1/4 inches by 7 3/4 inches

- 2 boards 14 1/2 inches by 7 3/4 inches

For more information on Sealed Box Calculator, click here.

Box Construction:

Note the following when building an enclosure:

Apply wood glue to all fastening joints. The glue provides additional strength to the joints.

Apply silicon caulk to all internal joints. This will ensure any leaks in the enclosure are sealed. A small leak can produce noticeable noise and degraded sound output of the enclosure.

- Needs to be strong enough to withstand the energy produced by the driver

- Needs to be airtight

- 1 inch high density particle board. (3/4 inch particle board can be used for smaller drivers)

- 1 1/2 inch screws. Do not use nails. Nails will vibrate out of the wood

- High quality wood glue (Elmer's wood glue)

- Silicon caulk

Apply wood glue to all fastening joints. The glue provides additional strength to the joints.

Apply silicon caulk to all internal joints. This will ensure any leaks in the enclosure are sealed. A small leak can produce noticeable noise and degraded sound output of the enclosure.

Infant Growth Charts - Baby Percentiles

Overtime Pay Rate Calculator

Salary Hourly Pay Converter - Jobs

Percent Off - Sale Discount Calculator

Pay Raise Increase Calculator

Linear Interpolation Calculator

Dog Age Calculator

Heat Index Weather Calculator

Subwoofer Box Calculator

Ported Subwoofer Box Calculator

Bandpass Subwoofer Box Calculators

Sealed Subwoofer Box Calculators

Subwoofer Related Design Calculators

Closed Subwoofer Box Calculator

Ohm Law Calculator

Darcy Minor Loss Calculator

Home: PopularIndex 1Index 2Index 3Index 4Infant ChartMath GeometryPhysics ForceFluid MechanicsFinanceLoan CalculatorNursing Math

Online Web Apps, Rich Internet Application, Technical Tools, Specifications, How to Guides, Training, Applications, Examples, Tutorials, Reviews, Answers, Test Review Resources, Analysis, Homework Solutions, Worksheets, Help, Data and Information for Engineers, Technicians, Teachers, Tutors, Researchers, K-12 Education, College and High School Students, Science Fair Projects and Scientists

By Jimmy Raymond

![]()

Contact: aj@ajdesigner.com

Privacy Policy, Disclaimer and Terms

Copyright 2002-2015